The Secret Life of Projector Motors: Repairing and Replacing Drive Motors

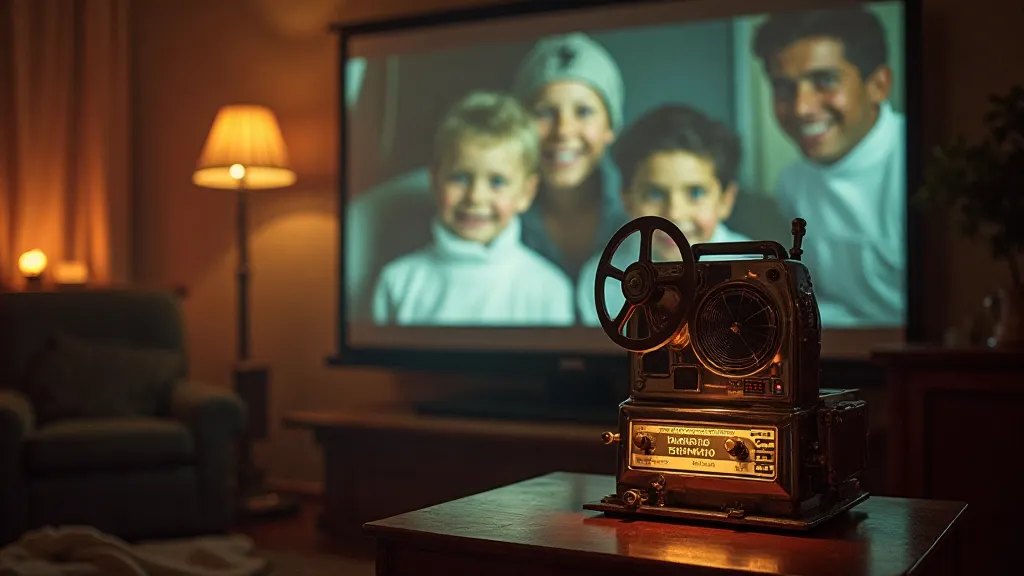

There's a peculiar romance in the ticking, whirring, and occasional protesting sounds of a vintage slide projector. It’s a soundscape that transports you back to a time when sharing memories wasn't about likes and fleeting digital images, but about communal gatherings, meticulously curated slides, and the palpable anticipation as the next scene unfolded on a projected image. At the heart of that experience, often overlooked, lies the projector’s motor - a surprisingly complex and vital component. While the optics and lamps often steal the spotlight, it's the motor that dictates the projector's rhythm, its ability to advance slides, and ultimately, its reliability. Ignoring its subtle cues can be the first step towards a beautifully crafted machine falling silent.

I remember the first time I disassembled a slide projector motor. It was a Kodak Carousel, a legend in its own right. The chrome gleamed, the mechanisms felt robust, and I felt a sense of reverence, like I was handling a piece of finely engineered clockwork. The motor itself, a compact marvel of gears, brushes, and a surprisingly intricate escapement, held a silent story of countless projections, family gatherings, and shared laughter. That initial disassembly sparked a fascination that continues to this day, a deep appreciation for the ingenuity and craftsmanship that went into these machines.

The history of slide projectors is intertwined with the rise of consumer photography and the desire to share images on a grander scale. Early photographic processes, like daguerreotypes and tintypes, were cumbersome and expensive. As photographic technology improved, the availability of dry plates and, later, color transparency film, made slide photography accessible to a wider audience. Companies like Kodak, Canon, and Braun invested heavily in developing slide projectors, resulting in a wave of elegant and reliable machines that defined a generation. The motors within these projectors were specifically engineered for smooth, consistent operation - a far cry from the noisy, less sophisticated motors of other appliances.

Understanding the Motor’s Role

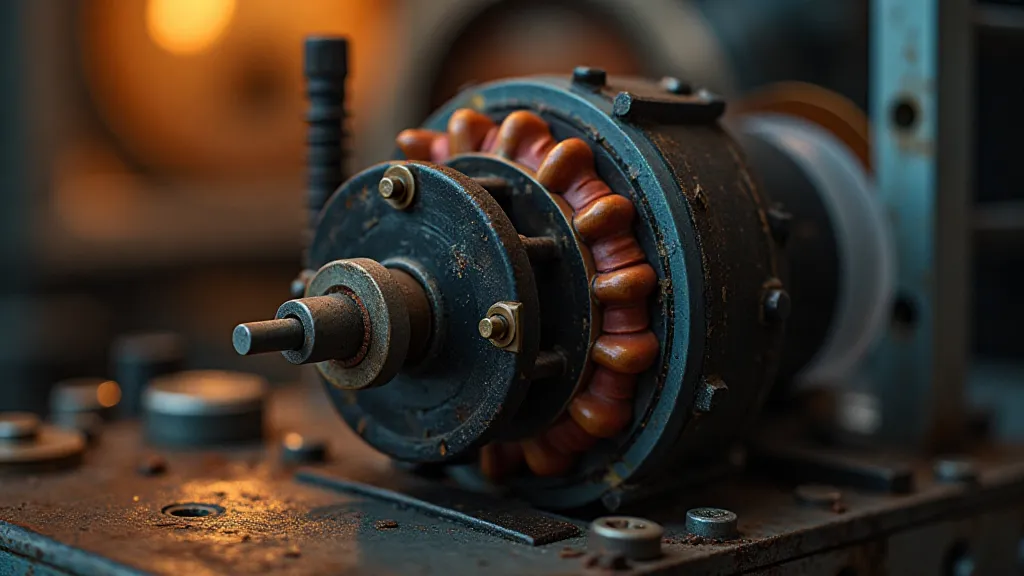

The motor's primary function is to advance the slides in a consistent and timed manner. But it also often regulates the lamp's operation, controlling brightness and exposure. The slide advance mechanism typically involves a gear train connected to the motor’s shaft. This train translates the motor's rotation into a step-by-step movement that pushes the slides along the carousel or magazine. A crucial element is the escapement, which ensures precise timing and prevents the motor from simply spinning out of control. The motor's speed is often regulated by a complex system of resistors and capacitors, ensuring that the slides advance at the correct pace for optimal viewing.

Motor problems are often a significant contributor to projector failure. Common issues include worn brushes, a seized commutator, a faulty capacitor in the speed control circuit, or simply a lack of lubrication leading to binding gears. Even a seemingly minor problem, like a slightly loose screw, can disrupt the delicate balance of the mechanism and cause erratic behavior.

Troubleshooting Motor Issues

Before attempting any repairs, it’s crucial to thoroughly diagnose the problem. Visually inspect the motor for any signs of physical damage, such as cracks, corrosion, or loose connections. Listen carefully to the motor’s sound. A grinding noise usually indicates worn brushes or a seized commutator. A rattling sound can be caused by loose gears or a faulty capacitor. A motor that simply doesn't run suggests a more serious electrical problem.

Testing the motor's electrical performance is essential. Using a multimeter, you can check the continuity of the windings, the voltage across the capacitor, and the resistance of the brushes. However, electrical troubleshooting requires a good understanding of basic electronics and should only be attempted by those comfortable with such tasks.

Often, the simplest fixes can resolve motor problems. Cleaning the commutator with fine-grit sandpaper can remove oxidation and improve contact. Replacing worn brushes is a relatively straightforward task that can restore smooth operation. Lubricating the gears and bearings with a high-quality synthetic lubricant can reduce friction and extend the motor’s lifespan.

Replacing the Motor – A Last Resort

If the motor is severely damaged or beyond repair, replacement is the only option. Sourcing a replacement motor can be challenging, as these components are often no longer manufactured. However, online auction sites and vintage equipment dealers are good places to look. It's crucial to find a motor that is compatible with your specific projector model. While there can sometimes be interchangeability between models, it is a risk, and careful research is required.

Replacing the motor involves disconnecting the old motor from the projector’s drive mechanism and connecting the new motor in its place. This is a delicate process that requires patience and a steady hand. Carefully document each step of the disassembly process, taking photographs or making detailed notes, so you can reassemble the projector correctly.

The Enduring Legacy of Analog Projection

Repairing vintage slide projectors is more than just fixing a machine; it’s preserving a piece of history. These projectors represent a time when technology was simpler, more reliable, and more focused on sharing experiences. The whirring motor, the beam of light illuminating a carousel of memories—these are the things that make vintage slide projection so special. It's a tactile, intimate experience that stands in stark contrast to the ephemeral nature of digital media.

The meticulous craftsmanship evident in these projectors is a testament to the dedication of the engineers and technicians who built them. Taking the time to understand and repair these machines is a way of honoring their legacy, keeping a unique and valuable part of our cultural heritage alive. There's a quiet satisfaction in breathing new life into these machines, allowing them to continue sharing stories for generations to come.

The sound of the motor, once a sign of impending stillness, can again be the soundtrack to cherished moments. It’s a small act of preservation, a refusal to let the analog world fade into obsolescence. It's a testament to the enduring power of shared experiences and the beauty of a well-crafted machine.